Gyunam Park

Assistant Professor at TU/e || Advisor at Fraunhofer FIT

Biography

I’m Gyunam Park, an assistant professor at the Process Analytics Cluster in the Department of Mathematics and Computer Science at Eindhoven University of Technology. I also serve as an advisor at Fraunhofer FIT. I am deeply passionate about providing fair, compliant, and transparent solutions to process-related problems. My current research interests are two-fold: 1) designing process mining methods to provide full transparency over processes and support process stakeholders to characterize fatal process problems and 2) developing responsible machine learning methods to provide responsible solutions to such process problems. I received my Ph.D. in Computer Science from RWTH Aachen University, Germany, my M.S. in Industrial Engineering from POSTECH, South Korea, and my B.S. in Computer Science/Technology Management from UNIST, South Korea.

DOWNLOAD CVTeaching

Research Projects

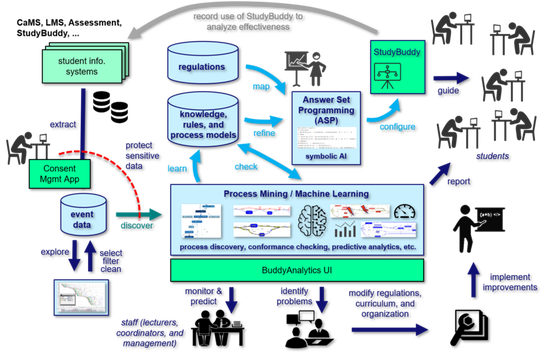

AIStudyBuddy

This project aims to introduce AI-driven resources and assessments to enhance the teaching and learning experiences for students and curriculum planners. The AI-enabled ‘study companion’ tool offers targeted assistance to students, like setting objectives to secure top grades in a course and generating suggestions to meet those objectives. The AI-integrated ‘companion analytics’ tool equips curriculum planners with dashboards and assists them in the process of (re)structuring study programs.

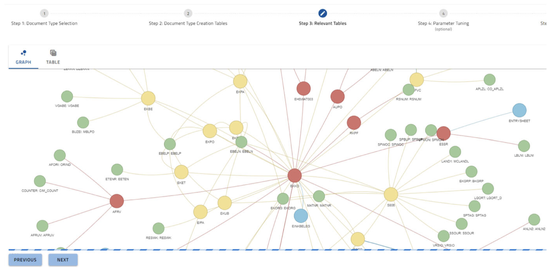

Process Mining over SAP Data (PM-SAP)

The initial and most costly phase in process mining involves retrieving, converting, and uploading event logs from information systems. Specifically, pulling event data from prevalent ERP platforms like SAP is a significant hurdle due to the data’s magnitude and organization. The purpose of this project is to first obtain object-focused event data from SAP ERP platforms, and then uncover and examine both familiar and unfamiliar processes within these systems.

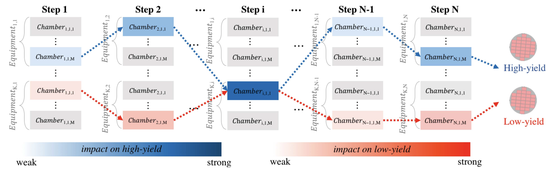

Development of best reference resource mining algorithm, in cooperation with Samsung Electronics

The importance of efficiently operating and managing manufacturing equipment in a process is highlighted in this research. By utilizing process mining techniques, analysis of equipment status and operation status becomes possible. The research aims to develop an equipment mining algorithm for deriving the Best Reference equipment. The study involves analyzing core semiconductor manufacturing processes, identifying problem equipment, engaging in process mining technology sensing activities that include technology and case introductions, and developing a methodology for identifying the Best Reference equipment using process mining techniques.

Software Projects